Management Materiality

The Sansha Electric Manufacturing Group identified seven material issues by evaluating stakeholders’ interests and degree of impact in its CF26 medium-term management plan. They have been integrated into our business strategy. We will carry out specific measures, enabling us not only to pursue growth and profit but also to help achieve the Sustainable Development Goals (SDGs) and create a sustainable society.

Rise of renewable energy and new energy

Risks

- Cost increase and capital investment burdens due to the introduction of new technologies

- Compatibility with power grids and supply instability

Opportunities

- Increased demand for products and services for a decarbonized society

Medium-term management plan (priority measures)

Semiconductor business

Power supply business

Progress of initiatives

- The 1700V/300A SiC MOSFET module and the 1700V SiC MOSFET discrete semiconductor were developed

- A high-speed diode module with high resistance to excessive voltages was developed

Result

- Energy loss was decreased by introducing a high efficiency SiC device

- Customers’ energy costs were reduced

- The renewable energy equipment adoption rate was increased

What we aspire to be ten years from now

- We will reduce the energy consumption of society as a whole by developing high- efficiency products

- We will lead the realization of a decarbonized society with the strength of technologies

- We will support the widespread use of renewable energy and new energy

- We will contribute to the development of the industry and the improvement of the quality of people’s lives through the stable supply of power

Rapid urbanization of emerging countries

Risks

- Political and economic instability and regulation risks

- Sharp increase in environmental impact and tight supply and demand balance for resources

Opportunities

- Contribution to demand for the construction of infrastructure

- Market expansion following the growth of the consuming population

Medium-term management plan (priority measures)

Semiconductor business

Power supply business

Progress of initiatives

- Power supplies for surface treatment were developed for Asia

Result

- The expansion of energy-efficient and high efficiency models led to compliance with environmental regulations in Asia and was a response to corporate customers’ sustainability- related needs

What we aspire to be ten years from now

- We will achieve the stable supply of power using high performance power semiconductors and power conversion technologies

- We will provide technologies supporting sustainable social infrastructure

- We will establish energy infrastructure supporting the continued development of the industry

Provision of safety and peace of mind

Risks

- Risk of accidents or lawsuits arising from product or service defects

- Risk of suspension of operations due to human error or disaster

Opportunities

- Differentiation through construction and the provision of safety management systems

- Increase of needs for services related to business continuity plans (BCPs)

Medium-term management plan (priority measures)

- Improving quality, cost and delivery (QCD) and providing added value to customers

Progress of initiatives

- Capital investments were made with a view toward the stabilization of the process for SiC products

- Sansha Solution Service Co., Ltd. shifted from an ordinary construction business license to a special construction business license

Result

- Quality was stabilized and improved

- Customer satisfaction and confidence improved

What we aspire to be ten years from now

- We will provide highly safe products based on the latest technologies and innovations

- We will establish a maintenance and management system using smart functions and artificial intelligence (AI)

- We will advance monitoring technologies to open the way to the real-time monitoring of product status

Technological progress

Risks

- Obsolescence of technologies and intensifying competition after technological innovation by competitors

- Shortage of workers with digital skills and delays in the introduction of technologies

Opportunities

- Improved productivity, efficiency and cost savings

- Creation of new added value (IoT, AI, robotics)

Medium-term management plan (priority measures)

Semiconductor business

Power supply business

Progress of initiatives

- Capital investments were made to increase semiconductor production

Result

- Production efficiency improved and delivery times shortened

- Customer satisfaction and confidence improved

What we aspire to be ten years from now

- We will increase productivity using automation, AI and IoT technologies

- We will achieve higher efficiency production processes and quality

- We will establish the ability to flexibly respond to diverse customer needs

Climate change

Risks

- Disruption of supply chains due to abnormal weather conditions and disasters

- Cost increase due to carbon taxes and stricter environmental regulations

Opportunities

- Acceleration of the shift to low-carbon products and energy-efficient equipment

Medium-term management plan (priority measures)

- Installing solar (PV) power generation system at the Okayama Plant

- Replacing the gas air-conditioning system at the headquarters with an electric system

- Replacing the air- conditioning system at the Okayama Plant

Progress of initiatives

- A solar (PV) power generation system for private consumption was installed at the Okayama Plant. It began operating in August 2024

- The air conditioning system at headquarters was switched from gas-powered to electricity-powered

Result

- The effect of the installation of the solar (PV) power generation system at the Okayama Plant was a 673 t-CO2 per year CO2 emissions reduction

- The revision of the energy mix at headquarters and the plants reduced environmental impact

What we aspire to be ten years from now

- We will maximize energy efficiency and reduce environmental impact

- We will reduce waste and popularize recycling to achieve resource circulation

- We will establish optimal logistics that include environmental considerations

Demographic change

Risks

- Labor shortage due to the aging of the population

- Decline in technological strengths caused by difficulties in acquiring human resources

Opportunities

- Acceleration of labor-saving measures through DX and automation

- Initiatives to support diverse work styles to strengthen the acquisition and retention of personnel

Medium-term management plan (priority measures)

- Cultivating a wide variety of personnel to create value

- Increasing the percentage of managers that are women

- Improving per-capita net sales and operating profit

Progress of initiatives

- Next-generation leaders were discovered and given training to cultivate them

- A rich training system including job-class-specific cultivation training programs was developed

Result

- Number and percentage of women in management positions

6 (4.8%) - Number and percentage of women that are leaders

40 (11.5%)

What we aspire to be ten years from now

- We will cultivate personnel who will create value

- We will construct a lively organizational culture

- We will achieve differentiation and continuous growth through innovation

Fragmentation of the world and cyberattacks

Risks

- Trade barriers due to geopolitical risks

- Confidential information leakage and the suspension of operations following a cyberattack

- Supply chain breakage

Opportunities

- Provision of secure power supplies

- Reconstruction of supply chains

Medium-term management plan (priority measures)

- Reviewing business continuity plans (BCPs)

- Making improvements related to information security issues and reviewing the system for handling incidents

Progress of initiatives

- The security of the virtual private network (VPN) was enhanced

- An endpoint detection and response (EDR) system was introduced

Result

- The ability to respond to cyberattacks was improved and a response system was built

What we aspire to be ten years from now

- We will establish a strong capacity to continue business and an information security system

- We will construct a system for swiftly and effectively responding to incidents

- We will increase competitiveness as an organization that enables people to trust it and provides them with a sense of security

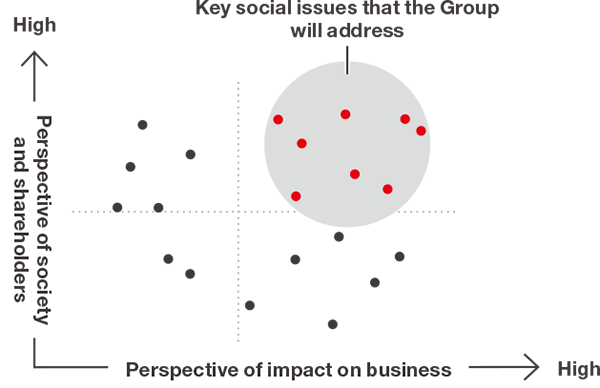

Process of identifying material issues

Business environment analysis

We analyzed the external environment surrounding the Group, such as political and economic trends in Japan and overseas, technological innovation, changes in regulations and shifts of industrial structure, from multiple perspectives. We paid particular attention to responses to carbon neutrality, energy conversion, progress in digitalization and other factors that will significantly change the industry, and we assessed their impact on the Group’s businesses. In addition, we clarified changes in the external environment and structural problems that would be important in the future allocation of management resources and value creation in consideration of consistency with the characteristics of our business.

Identify social issues

With a view toward the creation of a sustainable society, we referenced the SDGs, the United Nations Global Compact, the code of conduct in the industry (the Responsible Business Alliance (RBA) Code of Conduct)* and other international standards. In addition, in consideration of the GRI Standards, the ISO 26000 standard, other major guidelines and megatrends such as climate change, resource circulation, human rights and diversity, we selected a wide range of social issues that impact the Group.

- *

- The RBA Code of Conduct is guidance formulated for electronics industry and electric equipment-related industry supply chains.

Analyze the selected issues

We analyzed and assessed the selected social issues from the viewpoints of stakeholders’ interests, the size of their impact and their significance to the Group. Based on the results, we created a draft of our priority material issues that we should address as a business entity.

Identify and review material issues

This draft of material issues was deliberated by the management team and discussed and approved by the Board of Directors. The material issues thus identified have been incorporated into our medium-term management plan. We implement this plan in connection with our business strategy and sustainability strategy. We will continually review the appropriateness of the material issues at the same time as we update our medium-term management plan and on other occasions in view of the changes in the business environment and society.