News

2020.11.30

Expanded 1200V withstand voltage SiC MOSFET lineup that achieves high reliability and low loss

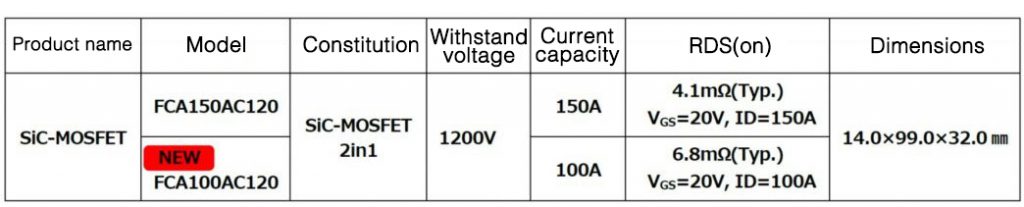

We developed a 100A SiC MOSFET module that uses a transfer Mold * package that is compact and has excellent long-term reliability. By adding the 100A product to the conventional 150A product, we are now able to meet a wide range of customer needs.

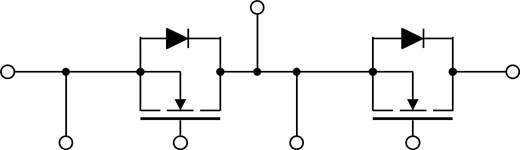

Connection diagram

* Transfer mold is a type of thermosetting resin molding method that heats the material to soften it and then press-fits it into the mold.

【Features】

Power devices are used in a variety of applications in the automotive and industrial fields. SiC (Silicon Carbide) power devices are expected to be key devices for energy saving in high current and high voltage applications because they can operate at low loss and high speed compared to conventional Si (Silicon). Our SiC MOSFET module uses a unique package “Techno Block * 1” to improve long-term reliability, reduce loss, and reduce size.

This product has been commercialized through joint development with Panasonic Corporation.

【Product overview】

【New product features】

- Our original package “Techno Block” that realizes improvement of long-term reliability * 2 and miniaturization. Internal structure that reduces the inductance that enables high-speed switching to about 1/2 (compared to our conventional products)

- Equipped with Panasonic Corporation’s original SiC MOSFET chip (DioMOS (Diode integrated MOSFET)) with a built-in regenerative diode function that can reduce unnecessary inductance to realize ideal switching.

- Industry-leading short-circuit withstand capability that realizes machinery safety design against short-circuit failure, which is said to be a weak point of SiC-MOS.

- On-resistance characteristics with little change even at high temperatures (150 ° C) when the chip realizes high-efficiency power during actual use

- Gate characteristics with a high threshold that is resistant to malfunction against noise during high-frequency driving (threshold voltage 4.0V (Typ.))

* 1 A package that combines the transformer fur mold method with a structure in which metal and chips are sandwiched by solder joining.

By not using wire bonding technology to connect, long-term reliability is improved and miniaturization is achieved.

Techno Block is a trademark of our company.

* 2 Power cycle capacity Approximately 3 times that of our conventional products

【Main applications】

・Industrial inverter

・DC-DC converter

・EV battery charger

・High output Resonant Power Supply

【Consideration for the environment】

This product complies with the RoHS * directive (2011/65 / EU and (EU) 2015/863).

※ Restriction of the use of certain Hazardous Substances in electrical and electronic equipment.

【Future outlook】

By expanding the lineup of transformer fur mold method packages and SiC-equipped products, which we are good at, we will contribute to high reliability and high-efficiency of Power supply, as well as miniaturization and cost reduction.

【Production plant】

Okayama Plant:1741 Kaki, Nagi-cho, Katsuta-gun, Okayama 708-1312, Japan

【Price】

Please contact our sales department.

* The information contained in this press release is as of the time of the announcement. Please note that the contents are subject to change without notice.