With Earth

The Sansha Electric Group considers the preservation of the global environment to be "our responsibility to the next generation" and recognizes that reducing the environmental impact of our business activities is one of our most important tasks, and we are accelerating our global environmental preservation activities.

Sansha Electric Manufacturing Group Environmental Policy

The Group is aware that conservation of the global environment is a corporate social responsibility. We will work to reduce environmental impact and consider biodiversity to aid the realization of a sustainable society.

- Observance of environmental laws and regulations

We will observe environmental laws and regulations and meet equivalent requirements. - Prevention of global warming

We will work to reduce greenhouse gas emissions from business activities - Contribution to a recycling-oriented society

We will strive to minimize waste and efficiently use resources to aid the realization of a sustainable recycling-oriented society. - Reduction of hazardous substances

We will work to reduce emissions of substances that adversely impact the environment and to prevent pollution - Consideration of biodiversity conservation

All our personnel will be aware of importance of conserving biodiversity and act in due consideration of it. - Reduction of the environmental impact of products

We will always strive to create environmentally-friendly product designs to provide products with little environmental impact throughout their life cycle - Continuous improvement of the environmental management system

We will be aware of impact our business activities and products have on the environment and work to continuously improve our environmental management system.

May 2010 Established

April 2023 Revised

Environmental Management System

The Board of Directors determines the basic policy on environmental initiatives and the Corporate Planning Conference, which is attended by the President and Executive General Managers, discusses specific actions and studies measures. Specific initiatives related to environmental protection and energy conservation are planned by the Environmental Management Implementation Committee, which meets regularly. The plans are discussed at the Corporate Planning Conference and decisions on them are made by the Board of Directors.

The Environmental Management Implementation Committee is composed of managers from individual departments and bases, and the Quality and Environment Planning Department acts as the administrative office for this committee.

Observance of Environmental Laws and Regulations

We understand the laws and regulations that apply to group companies as well as those that we should observe, and evaluate compliance regularly to ensure laws and regulations are observed.

ISO certifications we have acquired

| Certification body | Japan Quality Assurance Organization | |

|---|---|---|

| Registration number | Semiconductor Manufacturing Division | JQA-EM7548 |

| Power Supply System Manufacturing Division | JQA-EM7051 | |

| Date of registration | Semiconductor Manufacturing Division | June 28, 2019 |

| Power Supply System Manufacturing Division | February 14, 2014 | |

Global Warming Prevention Initiatives

Towards Carbon Neutrality in 2050

At the Sansha Electric Manufacturing Group, we recognize the importance of constantly lowering CO2 and waste emissions from production activities. Based on this understanding, we set the following goals in FY2021.

Reduction of CO2 emissions — Achievements and goals (Scope 1 and 2)

CO2 Reduction Initiatives

Sansha Electric Group aims to reduce CO2 emissions by 46% by 2030.

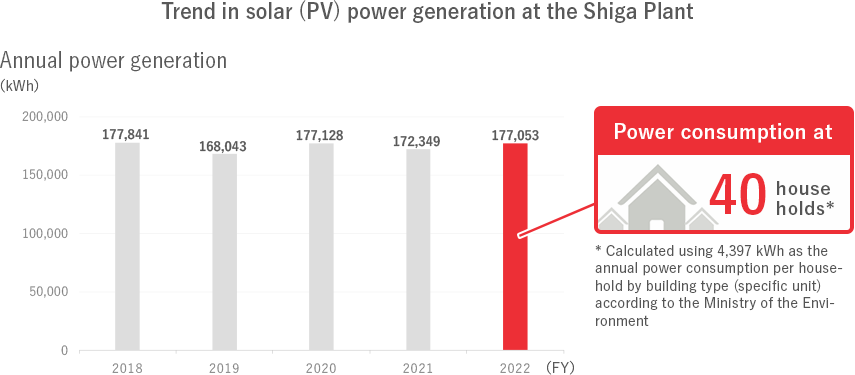

In 2014, the Shiga Plant was the first to install solar power generation equipment, and the Okayama Plant and Sansha Solution Service have installed solar power generation equipment for their own consumption.

The projected annual power generation is approximately 1,463,000 kwh, which is equivalent to the power consumption of 350 homes.

Actions at Okayama Plant

Achieving a departure from fossil fuels

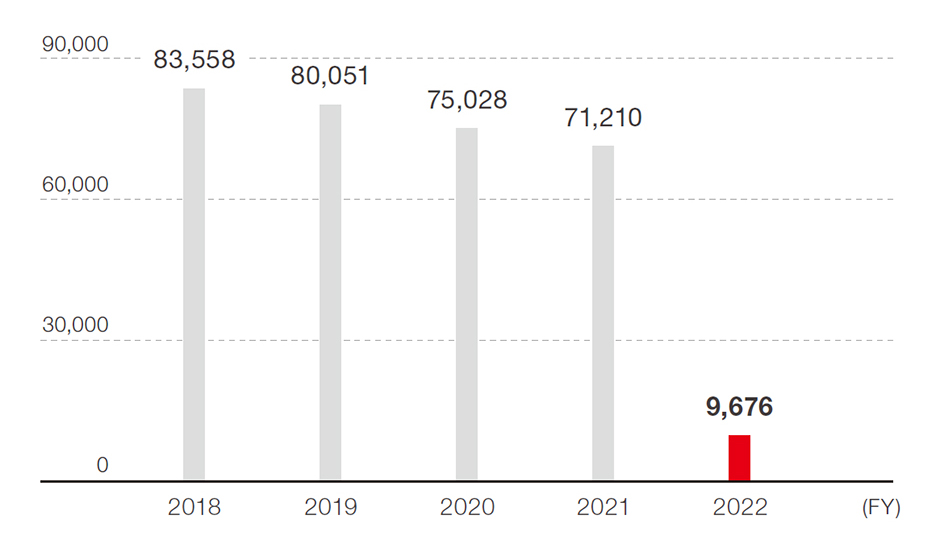

The Okayama Plant accounts for approx. 80% of the entire Group's total power consumption. At the plant, we have replaced the lighting system with an LED lighting system and introduced an Energy Management System (EMS). In addition, of two cleanroom buildings (Buildings A and B) that consume huge amounts of electricity because of the strict air-conditioning management that is required, we improved the efficiency of Building B's outside-air-processing air conditioners by renovating the existing heat source equipment (cold water chiller and steam boiler) to use a high-efficiency, air-cooled heat pump chiller and we also introduced variable flow control. Further, we have begun to use waste heat from production equipment to preheat and reheat outside air and we adopted a dry fog system for humidity control, which has led to the termination of steam humidification, which was the greatest challenge.

High-efficiency air-cooled modular chiller at the Okayama Plant- Heavy oil consumption at the Okayama Plant (liters)

Environmental Preservation Initiatives

Waste Reduction Achieved by Ending the Use of Plastic Packing Materials

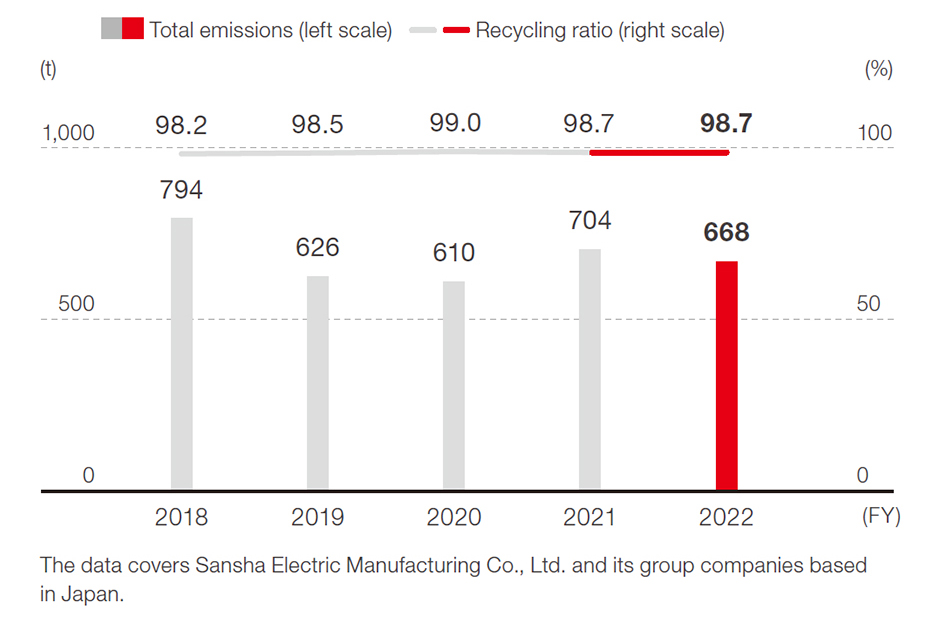

Waste emissions and recycling ratio

Our plants have been using reusable shipping containers and taking other actions in an effort to minimize waste emissions from business activities and to reduce packing materials and cushioning materials. In the future, at the Okayama Plant, we will successively replace plastic packing materials with cardboard for new products in a bid to reduce plastic consumption.

Efforts to Efficiently Use Water Resources

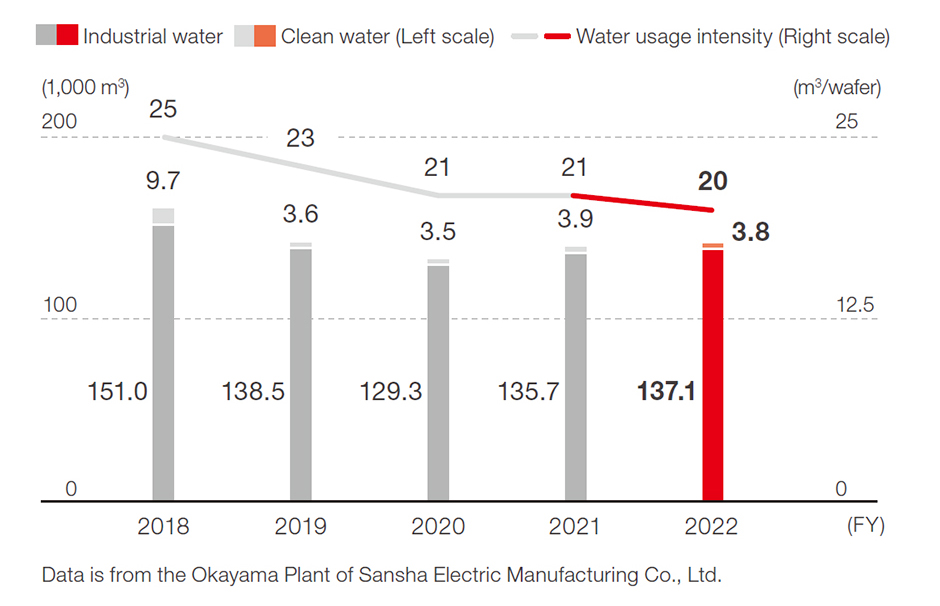

Water consumption

In recent years, we have seen various problems related to water occur, including water shortages attributed to droughts associated with climate change and flooding damage. The semiconductor manufacturing process necessarily consumes a vast amount of pure water for the removal of etching and cleaning chemicals and the cooling of equipment. At the Okayama Plant, we are striving to reduce water consumption by setting a reduction target for water consumption per wafer production volume, with the goal of promoting the efficient use of water resources.

In FY2022, water consumption increased due to the increase of production volume, but consumption per wafer decreased.

Initiatives for Controlling Water Quality

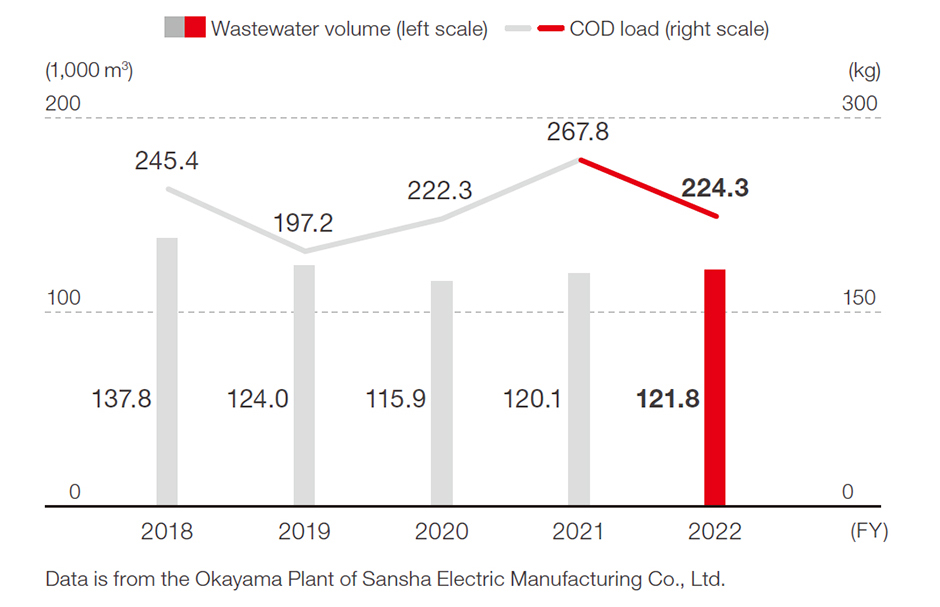

Wastewater volume and chemical oxygen demand (COD) load

At the Okayama Plant, wastewater from the manufacturing process is purified in a wastewater treatment facility and discharged only after meeting in-house standards, which are stricter than legal requirements.

We reduce and eliminate hazardous substances, recover hazardous substances that cannot be eliminated, and thoroughly monitor wastewater quality by conducting regular water quality inspections.

In FY2023, the wastewater discharge decreased compared to the previous year, but the COD load was found to have increased.

The Okayama Plant discharges wastewater that meets strict standards, but the COD load has increased.

Factors may include increased production volume and delays in process improvement.

The Okayama Plant will continue its efforts to minimize its environmental impact.

The Sha Denki Group has set a goal of reducing CO2 emissions by 46% by 2030.

In 2014, the Shiga Plant was the first to install solar power generation equipment, and the Okayama Plant and Sansha Solution Service have installed solar power generation equipment for their own consumption.

The projected annual power generation is approximately 1,463,000 kwh, which is equivalent to the power consumption of 350 homes.

Energy conservation efforts in the clean room at the Okayama Plant

Our Okayama Plant, which accounts for approximately 80% of our group's energy consumption, has been working on "moving away from fossil fuels" since fiscal year 2013. Their efforts in achieving energy conservation have been recognized, and they have been awarded "The Energy Conservation Center, Japan Chairman's Award" in the Best Practice Category of the "2023 Energy Conservation Grand Prize."

Overview of the Initiative

We improved two factory buildings that require high cleanliness levels.

From fiscal year 2017, we implemented LED lighting and introduced an energy management system, while also enhancing the efficiency of the outdoor air treatment air conditioning system in Building B. Specifically, we replaced the existing heat source equipment (cold water chillers and steam boilers) with high-efficiency air-cooled heat pump chillers, and simultaneously improved the variable flow control. Furthermore, we adopted waste heat recovery from production equipment for outdoor air preheating and reheating, and implemented a dry fog system for humidity control, which led to the elimination of steam humidification, our biggest challenge. Following Building B, we completed the renovation of Building A, achieving energy conservation in both buildings.

Compliance with the RoHS Directive

Sansha Electric Group's power semiconductor products are compliant with the RoHS Directive and can be used with peace of mind. In terms of other environmental measures, we are working to replace materials, solvents and other substances used, selecting substances with low environmental impact and managing them appropriately.

What is the RoHS Directive?

The RoHS Directive is an EU law on the restriction of the use of certain hazardous substances in electrical and electronic equipment, etc. Abbreviation for Restriction of Hazardous Substances, also known as the Restriction of the Use of Hazardous Substances Directive in Japanese The restrictions on use began on 22 July 2019.

Management of chemical substances

At the Sansha Electric Manufacturing Group, we manage chemical substances under the following policies, with an integrated approach that gives top priority to protecting the environment and ensuring safety.

| Protecting the environment | Under the Sansha Electric Manufacturing Group Environmental Policy, we minimize the environmental risks of chemical substances by reducing the use of such substances by improving the manufacturing process and productivity. Pursuant to the PRTR Act, we check and aggregate the amounts of chemical substances handled, emitted, and transferred outside and observe regulatory requirements. * PRTR Law Establishes a system under which the sources and quantities of chemicals that involve environmental pollution risks that are released into the environment, such as the air, water or soil, and the quantities of these chemicals that are moved in the form of waste (amount transferred outside) are assessed, calculated and published. |

|---|---|

| Ensuring safety | We take thorough measures to manage chemical substances appropriately and ensure safety throughout the process from purchase to manufacturing and disposal. We ensure the safety of employees by strengthening measures to handle accidents and work management. |

| Tracking and updating information | We obtain safety data sheets (SDS) to update information regularly and take appropriate measures when relevant laws have been revised. We establish a system for responding immediately to new information and regulatory requirements at engineering department and manufacturing sites. |

| Sustainability initiatives | We promote the use of sustainable materials such as selecting those with a low environmental impact when adopting new materials. We will use resources efficiently by improving production process and yields. |

| Training | We provide employees with training related to the safe handling of chemical substances and the latest information about them, thus raising awareness. We communicate closely with stakeholders and share information about the management of chemical substances while securing transparency. |

Privacy Policy and Use of Cookies

Our website uses cookies to improve your experience. In order to continue browsing, we ask that you consent to the use of cookies. We do not obtain any personal information through cookies.If you decline the use of cookies, you will not be able to receive some of the services offered by the website.