With Customers

Our aim is to create and sell products that grow together with our customers, rather than just sell them for profit. To achieve this, we believe it is important to continue to provide detailed after-sales service and to listen to the voices of those in the field where our products are used, gather small needs, and develop these into product development.

We also aim to reduce the environmental impact of our products by providing support from product supply to after-sales service and disposal in accordance with product life cycle assessments.

Vision

Global Power Solution Partner

Continuing to be a partner that listens to customers and meets their expectations in the provision of solutions.

Solution Proposal

The Group conducts the integrated production of high-voltage and large-current power semiconductors and power supplies. This means that we internally conduct all processes ranging from wafer processing to package assembly for power semiconductors and every process from the development and design of circuit boards to their assembly for power supplies. This allows us to provide customers with the proposals that are best suited to their needs from the perspective of high efficiency, safety and other features.

The medium-term management plan states that one of the priority measures for the power supply business is to accelerate the proposal of systems that combine power conditioners with storage batteries and network functions, rather than proposals related to power conditioners alone. A strength of the Group is the flexibility of its development and manufacturing. We will help customers solve their problems by proposing systems based on this strength.

Total solution services deliver safe and secure power supplies

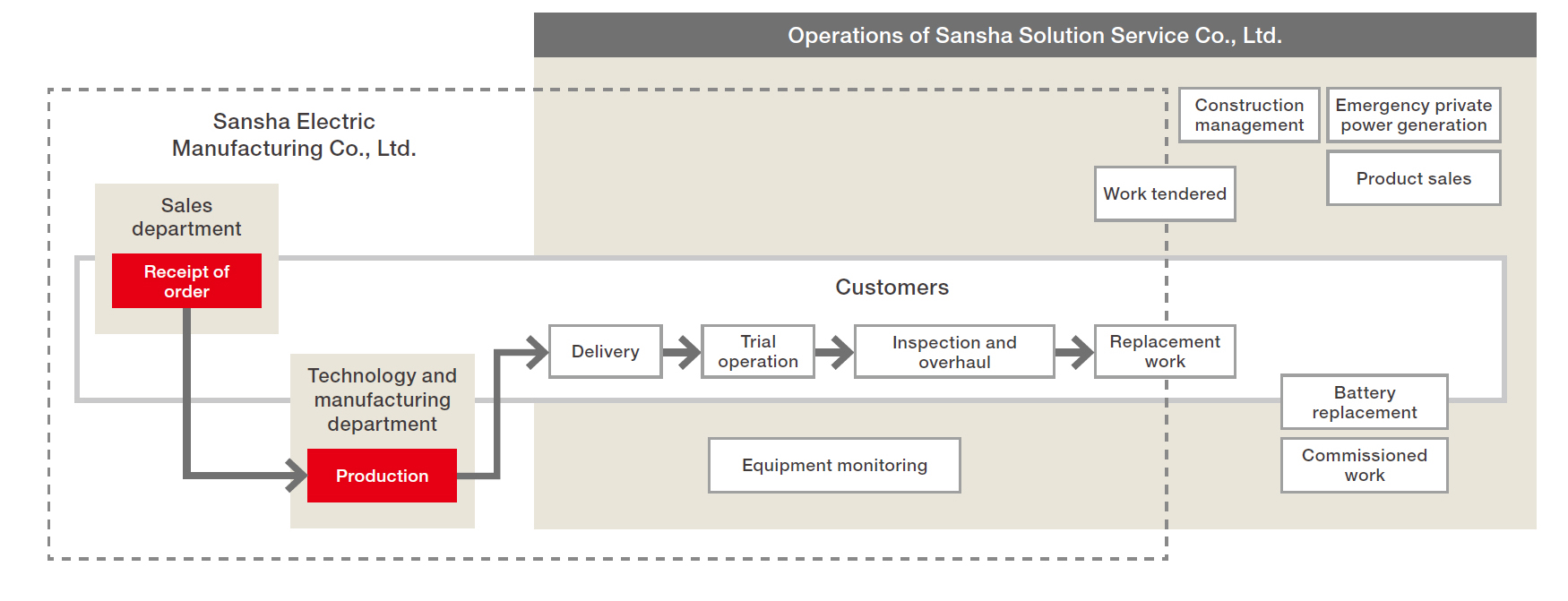

Sansha Solution Service Co., Ltd., a maintenance service company of the Sansha Electric Manufacturing Group, caters to customer needs with one-stop services including the installation of power supply equipment as well as the operation, maintenance and replacement of equipment under its policy of providing services which support the stable operation of power supply equipment.

Sansha Solution Service is implementing four priority measures in the medium-term management plan to enhance the total solution services of the Sansha Electric Manufacturing Group.

Sansha Electric Manufacturing Group's comprehensive solution services

Efforts to Improve Quality

The Group implements quality management attaching importance to increasing customer satisfaction and social value. We strive to create more value by appropriately managing products' safety, environmental performance, service life, maintainability and other elements, in addition to achieving product specifications, such as specifications for functionality and operability. Quality management is implemented by all organizations of the company and quality improvement activities are carried out continuously via management circles.

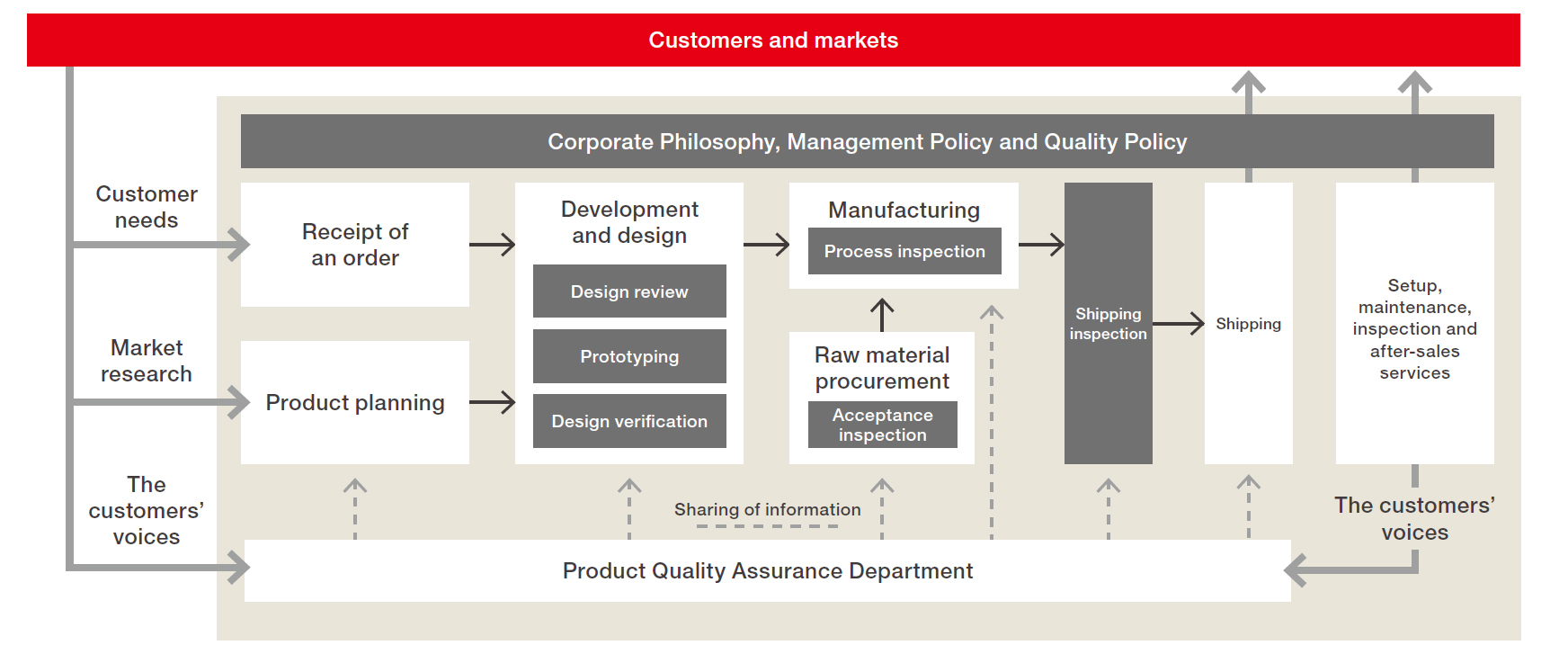

An important feature is that information can be shared seamlessly between the power semiconductor business and power supply business that uses power semiconductors. This has resulted in our skills for appropriately assuring quality and our after-sales services, in addition to sales activities and development and design in both businesses.

In addition, we focus on quality in all phases, from product planning to development, design, manufacturing and after-sales services and we provide feedback using the quality information collected by each section to the departments that need such information. This is how we improve product quality, with the goal of achieving sustainable growth.

Further, we have internal plants making plates, transformers, harnesses, printed circuit boards and other parts. This enables us to demonstrate our comprehensive ability to ensure high quality, which is our strength. We internally manage the quality of parts in our efforts to improve the quality of products as a whole.

Sansha Electric Manufacturing Group Quality Policy

The Group, with our primary corporate philosophy of 'constantly striving to create products that meet society's needs and contribute to societal progress through superior quality,' is dedicated to manufacturing that achieves customer satisfaction.

- Compliance

laws and regulationsComply with related laws, regulations and social norms. - Customer satisfaction

Make customer satisfaction the top priority and respond to the demand generated by society leveraging the high-level technological capabilities we have accumulated and strive to improve customer satisfaction. - Quality system

Refine quality with an integrated system including product planning, development, order acceptance, design, manufacturing and after-sales services to deliver reliability to customers. - Company-wide activities for quality improvement

Work together company-wide to improve quality through business improvement activities, the development of human resources and S-PS activities,* which are small-group activities unique to our company. - Continuous improvement of the quality management system

Establish a quality management system adapted to social environment and management environment and continue to improve it.

March 2016 Established

April 2023 Revised

Establishment and Operation of Quality Management Systems

Our Okayama Plant (semiconductors) and the Shiga Plant (power supply equipment) obtained ISO 9001 certification in 1996 and 1994 respectively, and have established a comprehensive quality management system and are committed to continuous quality improvement.

Quality assurance system diagram

QC Circle Activities

Since 1970, we have been engaged in QC circle activities called the SanRex Producer System (S-PS) activities. S-PS activities are based on QC circle activities and incorporate the policies of the company's organizations. Through these activities, we encourage employees to identify and solve problems and practice and learn methods for improving, in our efforts to improve their ability to execute business and further, to develop next-generation leaders. Another goal of these activities is to contribute to the establishment of rewarding workplaces with positive atmospheres.

Test Equipment That Contributes to Product Quality

To deliver reliable, satisfactory products to customers, we have installed and use a variety of test equipment to maintain the safety of our products and improve their quality.

Electromagnetic anechoic chamber and sealed room

In accordance with IEC standards (international standards for all electrical, electronic and related technologies) and other standards, we measure electromagnetic waves to see if our products affect other electric equipment and for other purposes.

Environmental test room

We conduct environmental performance tests to check our products' tolerance to low temperatures, high temperatures and high humidity.

The large testing chamber (see photo) is located at the Shiga Plant, while several smaller ones are installed at the head office and Okayama Plant.

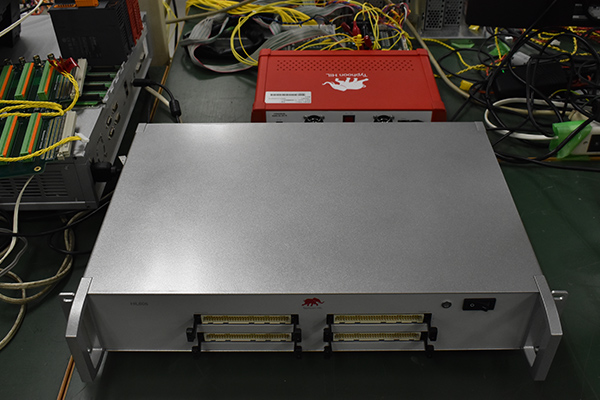

Software testing system interview

Previously, it was necessary to assemble hardware when verifying software. The introduction of this system enables us to test software without assembling hardware. We use this system to improve the efficiency of software development and improve quality.

Vibration test equipment

Vertical and horizontal tests are carried out in accordance with JIS standards, such as whether the product can withstand vibrations during transport, etc.

Drop test equipment

It has been tested in accordance with JIS standards to ensure that it will not break even if subjected to a drop impact.